Automatic L-Sealers

Value Series VSA1721

- Motorized seal height adjustment for various product sizes

- Insert style hot knife seal bar for consistent and clean seal

- Closing conveyor and dual photoeyes standard

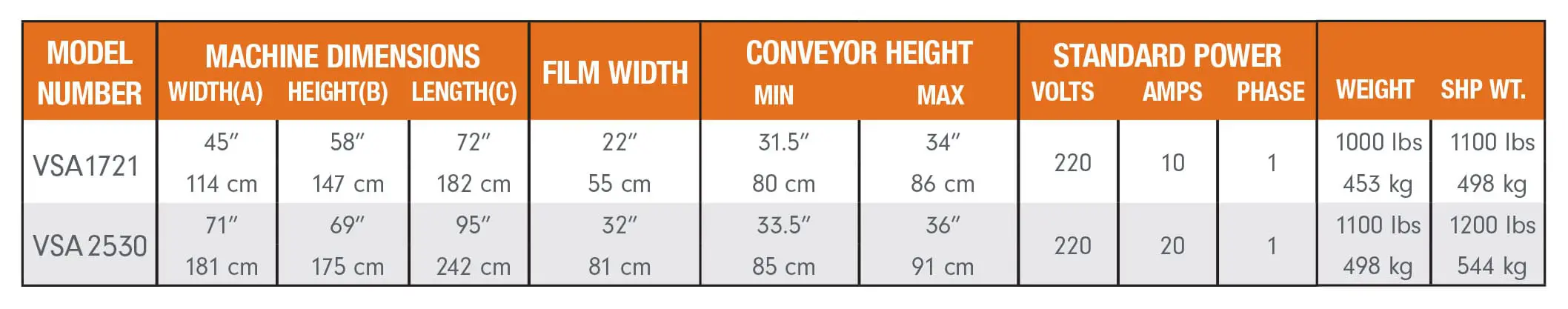

- HMI controller with simple menus for easy operation

- Film tracking wheels keep film in place

- 17”W x 21”L seal area

- Enclosed scrap rewind safely wraps up the scrap film

- Approx. 20-25 cycles/min depending on product size

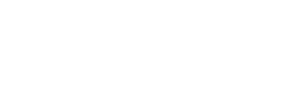

- VSA1721 Package Height: .2” – 4.75”

- Max. film width up to 22”

BUILT RIGHT...PRICED RIGHT

Proven reliable over and over again, these intermediate level EASTEY Automatic L-Sealers provide you with all the quality features found in much higher priced machines. They are designed and built to give you all the performance features needed for positive sealing a wide variety of films including polyolefin, polyethylene, and PVC.

PROVEN RELIABILITY, EFFICIENT DESIGN

Designed specifically for entry-level or intermediate applications that require simple operation, small footprint, or a limited budget, Eastey’s Value-Series Automatic L-Sealers will handle the day to day abuse required for automatic sealing.

The VSA1721 HMI user interface features simple menus for easy operation and adjustments required for a variety of applications.

The VSA2530 HMI user interface features simple menus for easy operation and adjustments required for a variety of applications

Provides a smooth transition from the seal area to the shrink tunnel.

Scrap unwind automatically wraps up the scrap film left from the sealer.

Adjustable pin perforator provides air evacuation in the film for clean and tight film shrinkage.

Automatic closing conveyor bridges the gap for a clean product transfer, then retracts to make way for the hot knife seal bar to make a clean and consistent seal.

Videos

Shrink Samples

- Designed to seal most polyolefin, polyethylene, and PVC shrink films

- Normal speed infeed and outfeed conveyors

- High speed with product indexing

- Motorized seal height adjustment for various product sizes

- Seal head equipped with pneumatic air cylinder for automatic sealing

- Hot knife seal bar for consistent and clean seal

- Consistent pressure across seal bar

- Closing conveyor bridges the gap for a clean product transfer, then retracts for the seal bar

- Automatic cycle timing with adjustable dwell time

- HMI controller with simple menus for easy operation

- Film tracking wheels keep film in place

- Multiple pin perforator provides precise air evacuation

- Heavy duty casters for transportation within plant

- Leveling legs provide sturdy base once in place

- VSA1721 features a 17”W x 21”L seal area

- VSA2530 features a 25”W x 30”L seal area

- Scrap unwind automatically wraps up the scrap film left from the sealer

- Easy to use design requires minimal training and maintenance

- VSA1721 Packaging Capacity: approx. 20-25/min depending on product size

- VSA2530 Packaging Capacity: approx. 15/min depending on product size

- VSA1721 Package Height: .2” – 4.75”

- VSA1721 maximum film width up to 22”

- VSA2530 maximum film width up to 32”

- Maximum film roll OD up to 12”

- 80 psi

- Available in 220v