Automatic L-Sealers

Professional Series

- Soft start infeed and outfeed conveyors to reduce shifting of products

- Variable speed infeed and outfeed conveyors

- Seal head casting equipped with pneumatic air cylinder

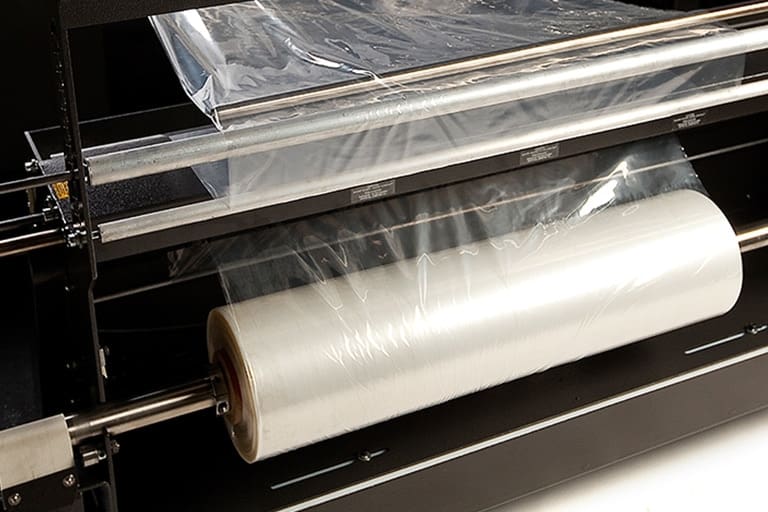

- Power film unwind ensures proper tension of film

- PLC controlled with product indexing

- Power film take-up scrap winder included

- Custom two-part epoxy finish resists scratching

- Side seal size 30”, 40” or 50”

- Front seal size 50”, 70”, or 100”

- Maximum film width up to 60”

- Maximum film roll OD up to 12”

BUILT RIGHT...PRICED RIGHT

Proven reliable over and over again, Eastey’s Automatic L-Sealers provide you with all the quality features found in much higher priced machines. They are designed and built to give you all the performance features needed for positive sealing a wide variety of films including polyolefin, polyethylene, and PVC.

PROVEN RELIABILITY, EFFICIENT DESIGN

Designed specifically for large or heavy products that need to be fully enclosed, Eastey Professional Series Automatic L-Sealers are constructed of expertly welded 1/4 cold rolled steel and designed to handle the day to day abuse of even the most challenging automatic sealing applications. The efficient automatic self centering seal system allows users to automatically seal product that is placed on the infeed conveyor for a consistent seal every time.

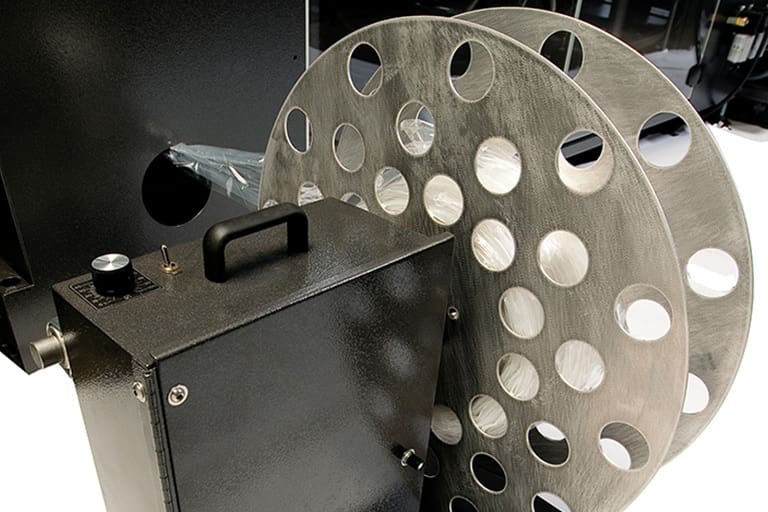

Power film unwind ensures proper tension of film.

Easy to use control panel lets users adjust for their specific application.

Film take-up scrap winder automatically wraps up the scrap film left from the sealer.

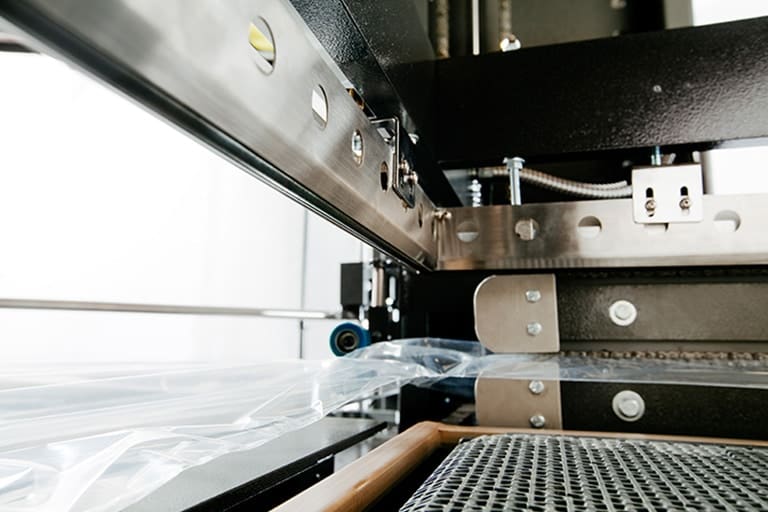

Hot knife seal system ensures a clean, positive, and even seal every time.

Optional PTFE coated mesh belting overlay is designed for no-stick operation with polyethylene films.

Videos

Shrink Samples

- Designed to seal most polyolefin, polyethylene, and PVC shrink films

- All-welded main frame from ¼” cold rolled steel

- Soft start infeed and outfeed conveyors to reduce shifting of products

- Variable speed infeed and outfeed conveyors

- Side adjustable film rack for perfect alignment

- Seal head casting equipped with pneumatic air cylinder for automatic sealing

- Hot knife seal available with mushroom (standard), pancake, arrow, or poly inserts

- Consistent pressure across seal bar

- Automatic cycle timing with adjustable dwell time

- PLC controlled with product indexing

- Film tracking wheels keep film in place

- Power film unwind ensures proper tension of film

- Multiple pin perforators provide air evacuation

- Power Film take-up scrap winder included

- Custom two-part epoxy finish resists scratching

- Heavy duty casters for transportation within plant

- Easy to use design requires minimal training and maintenance

- Side seal size 30”, 40” or 50”; front seal size 50”, 70”, or 100”

- Maximum film width up to 60”

- Maximum film roll OD up to 12”

- 60 PSI

- Available in 220v, or 480v

- Made in the USA