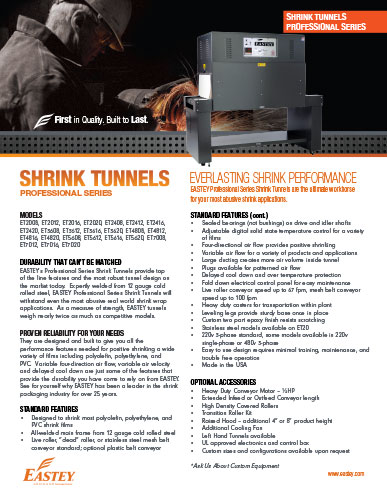

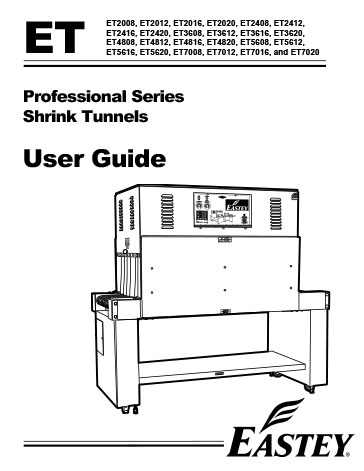

Professional Series Shrink Tunnels

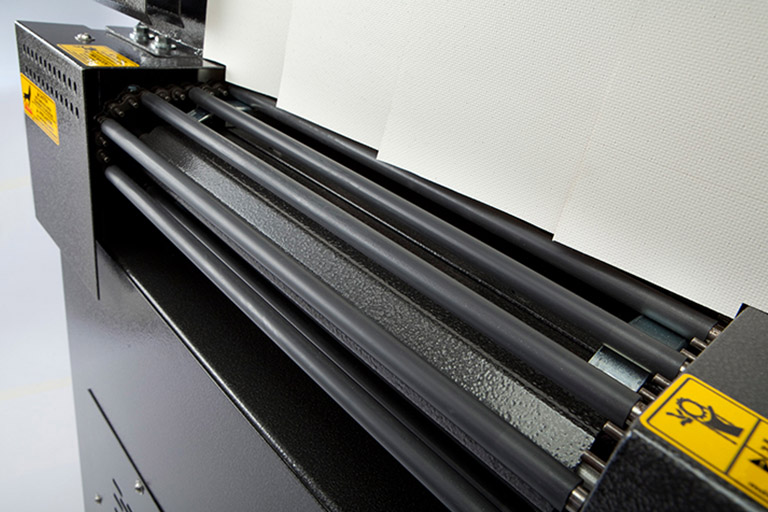

EASTEY’s Professional Series Shrink Tunnels provide top of the line features and the most robust tunnel design on the market today. Expertly welded from 12 gauge cold rolled steel, EASTEY Professional Series Shrink Tunnels will withstand even the most abusive real world shrink wrap applications. As a measure of strength, EASTEY tunnels weigh nearly twice as much as competitive models.

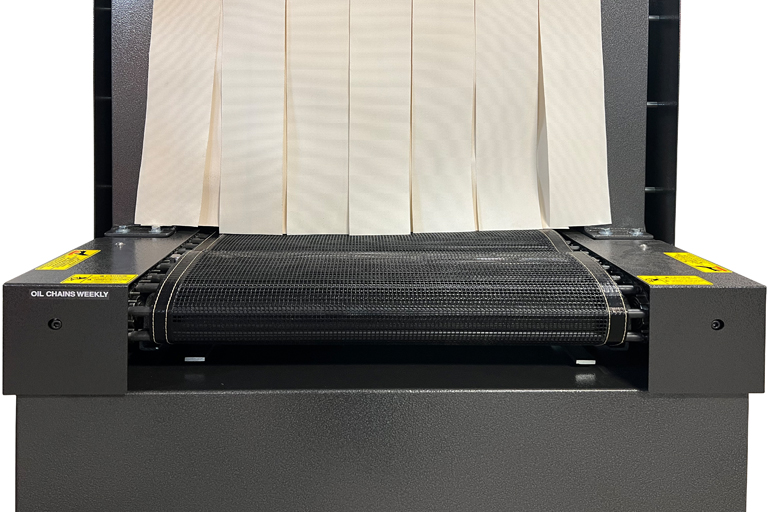

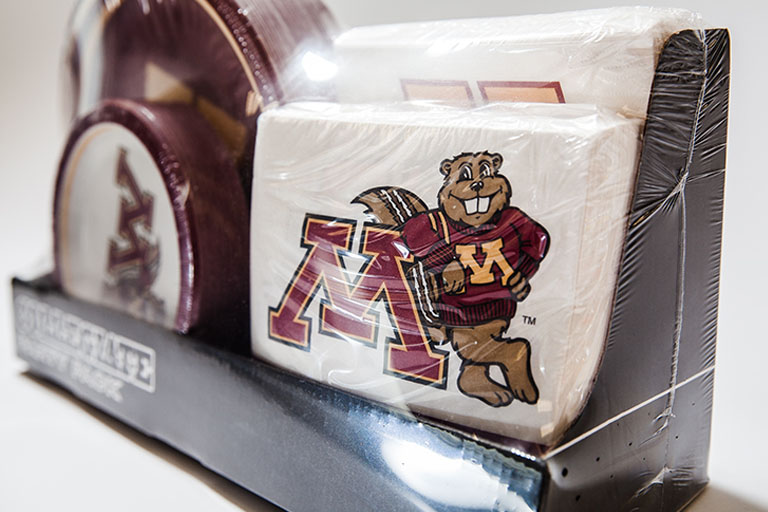

They are designed and built to give you all the performance features needed for positive shrinking a wide variety of films including polyolefin, polyethylene, and PVC. Variable four-direction air flow, variable air velocity and delayed cool down are just some of the features that provide the durability you have come to rely on from EASTEY. See for yourself why EASTEY has been a leader in the shrink packaging industry for over 25 years.