VCTS

Vertical Case Transport System

- Used for off-line case printing or labeling

- Ability to print or label all four panels of a case

- Holds up to 90 flat cases (single wall)

- Simple control interface

- Jog and Run mode

- Programmable counter for batch runs, rate metering, and elapsed counting

- Can be programmed to shut down at max count

- Emergency stop button for safe operation

OUR INNOVATIONS MEET YOUR NEEDS

Eastey’s Vertical Case Transport System allows users to print on two or four adjacent sides of a case eliminating the need for pre- printed cases or expensive labeling equipment and supplies. Adjustable width settings on our standard VCTS allow users to print on cases ranging in size from 10” x 10” up to 33” x 29”. A larger VCTS -XL allows cases from 21” x 10” up to 48” x 29”.

AUTOMATIC OPERATION

Designed for off-line case printing, the VCTS automatically feeds blank cases through a print station that is ideal for mounting hi- resolution inkjet printers and offers the ability to print virtually anywhere on either side of the case. Open access to printheads allows for easy maintenance and quick adjustments. The VCTS features an input hopper that has a capacity of up to 75 flat single wall RSC; up to 3⁄4 magazine capacity and can easily be reloaded by one person.

EASY TO PROGRAM

The VCTS includes a programmable counter that keeps track of batch quantities, rate of operation, and elapsed run time, allowing users the ability to customize case runs. The system can be easily programmed to shut down when the maximum count is reached. The VCTS batch counter is the ideal solution for users looking to print a message on specific number of cases while eliminating the need for.

CONVENIENT CASE COLLECTION

Eastey’s exit hopper collection bin is a convenient way to collect cases fed through the VCTS. The exit hopper is adjustable to accommodate the available box sizes in both the VCTS standard and VCTS-XL models. The collection bin conveniently collects up to 75 flat single wall RSCs and keeps them stored upright until they can be transported to another area. Vertical Case Transport Systems can be ordered with an exit hopper, one can be added at a later day, or a collection bin can be ordered as an option and integrated with previous VCTS systems.

INCREASED INVENTORY SPACE

Eastey’s VCTS is an ideal option for users who are looking to increase storage space by eliminating pre-printed case inventories. Equipped with casters, the VCTS can be easily moved throughout the plant to accommodate your various printing needs.

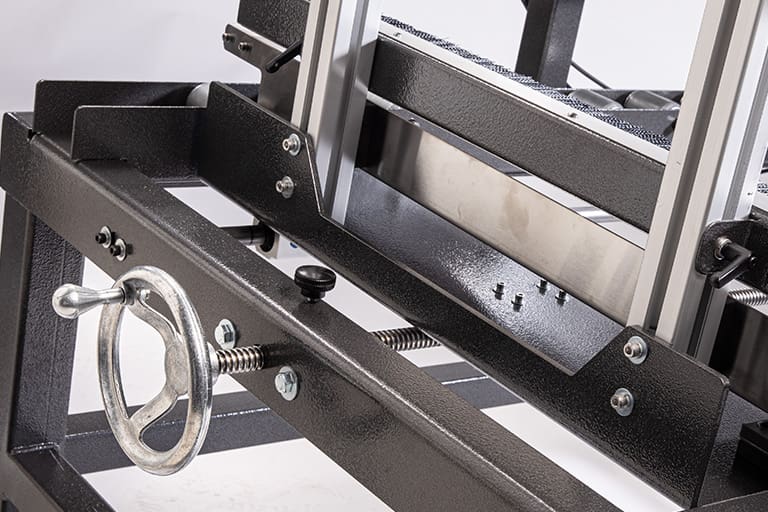

Adjustable collector bin with ruler to easily switch between different width cases.

Simple and rugged control interface for easy operation.

Hand crank wheel easily adjusts width of collector bin.

Pneumatic pusher arm can be adjusted for different width cases.

Videos

Case Handling Samples

- Plug-in and go operation

- Fast and easy box size changes

- Powder coated 12 gauge steel

- Low maintenance and easy to use

- Industrial strength side belts

- Accommodates wide range of box sizes

- Easy to load input hopper

- Optional exit hopper for easy case collection

- Adjustable leg extensions

- Simple integration with ink jet printers

- Heavy duty locking casters