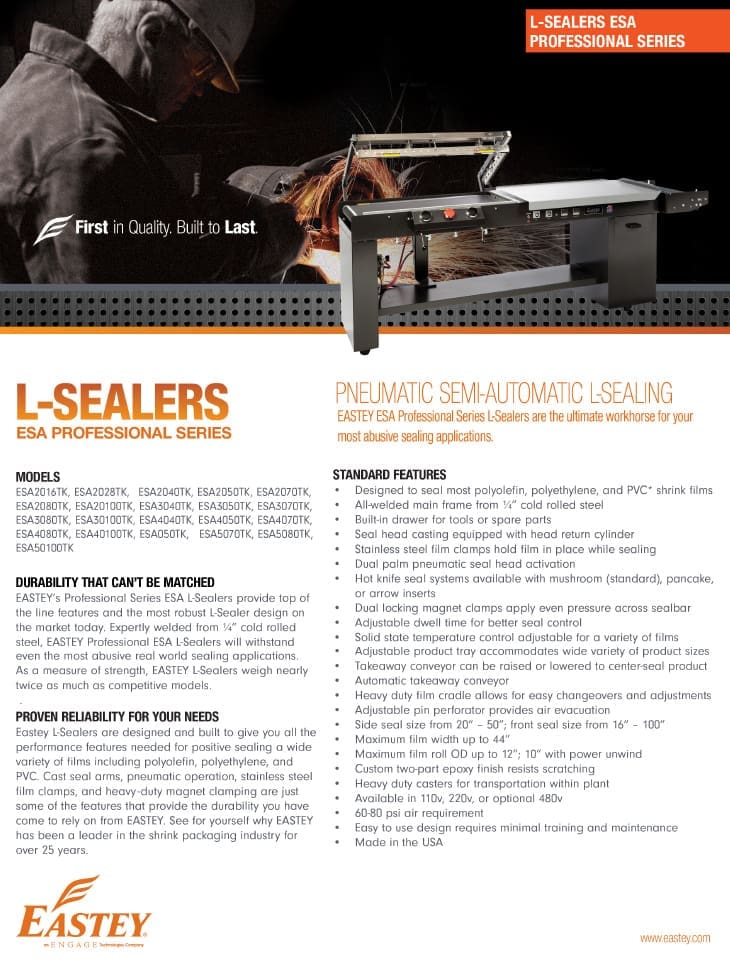

Professional Series

ESA Pneumatic L-Sealers

- Designed to seal most polyolefin, polyethylene, and PVC* shrink films

- All-welded main frame from ¼” cold rolled steel

- Side seal size from 20” – 50”; front seal size from 16” – 100”

- Maximum film width up to 44”

- Maximum film roll OD up to 12”; 10” with power unwind

DURABILITY THAT CAN’T BE MATCHED

EASTEY’s Professional Series ESA L-Sealers provide top of the line features and the most robust L-Sealer design on the market today. Expertly welded from ¼” cold rolled steel, EASTEY Professional ESA L-Sealers will withstand even the most abusive real world sealing applications. As a measure of strength, EASTEY L-Sealers weigh nearly twice as much as competitive models.

PROVEN RELIABILITY FOR YOUR NEEDS

Eastey L-Sealers are designed and built to give you all the performance features needed for positive sealing a wide variety of films including polyolefin, polyethylene, and PVC. Cast seal arms, pneumatic operation, stainless steel film clamps, and heavy-duty magnet clamping are just

some of the features that provide the durability you have come to rely on from EASTEY. See for yourself why EASTEY has been a leader in the shrink packaging industry for over 30 years.

Hot knife configuration.

Adjustable product tray easily separates film and accommodates variety of product sizes.

Heavy duty film cradle allows for quick and easy adjustment and changeover.

Adjustable pin perforator provides air evacuation in film.

Simple, easy to use control panel with automatic cycle timing and adjustable dwell time.

Dual palm seal head activation.

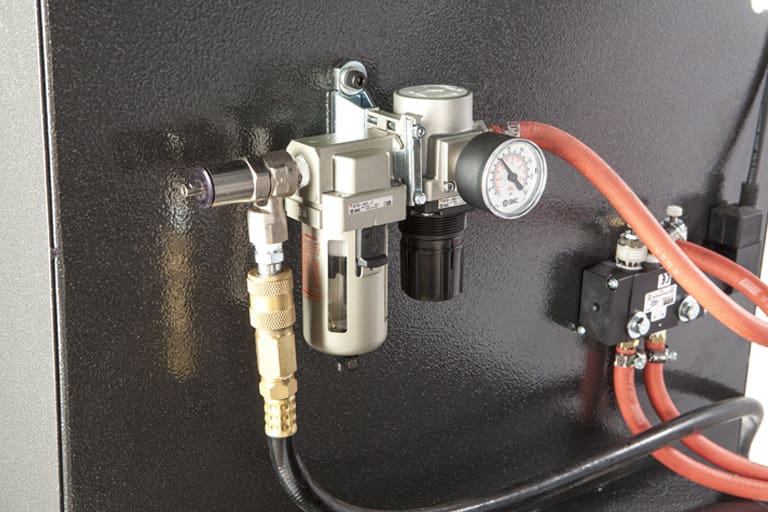

Pneumatic cylinder.

60 – 80 psi air connection manifold.

Videos

Shrink Samples

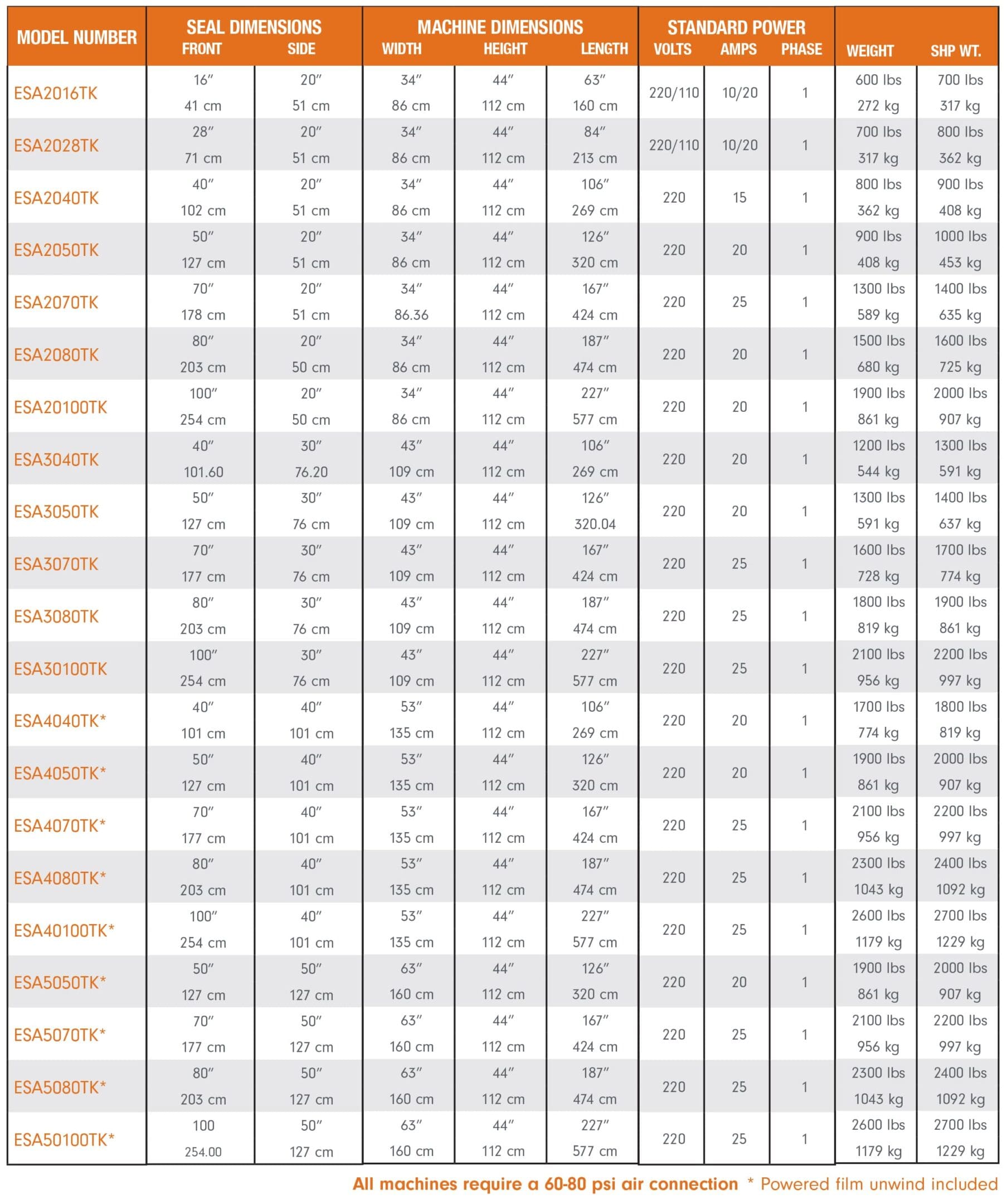

- Designed to seal most polyolefin, polyethylene, and PVC* shrink films

- All-welded main frame from ¼” cold rolled steel

- Built-in drawer for tools or spare parts

- Seal head casting equipped with head return cylinder

- Stainless steel film clamps hold film in place while sealing

- Dual palm pneumatic seal head activation

- Hot knife seal systems available with mushroom (standard), pancake, or arrow inserts

- Dual locking magnet clamps apply even pressure across sealbar

- Adjustable dwell time for better seal control

- Solid state temperature control adjustable for a variety of films

- Adjustable product tray accommodates wide variety of product sizes

- Takeaway conveyor can be raised or lowered to center-seal product

- Automatic takeaway conveyor

- Heavy duty film cradle allows for easy changeovers and adjustments

- Adjustable pin perforator provides air evacuation

- Side seal size from 20” – 50”; front seal size from 16” – 100”

- Maximum film width up to 44”

- Maximum film roll OD up to 12”; 10” with power unwind

- Custom two-part epoxy finish resists scratching

- Heavy duty casters for transportation within plant

- Available in 110v, 220v, or optional 480v

- 60-80 psi air requirement

- Easy to use design requires minimal training and maintenance

- Made in the USA

*With Hot knife systems only