Our Group Support and

Maintenance Programs at Eastey

Engage Packaging Group Support Assurance Program

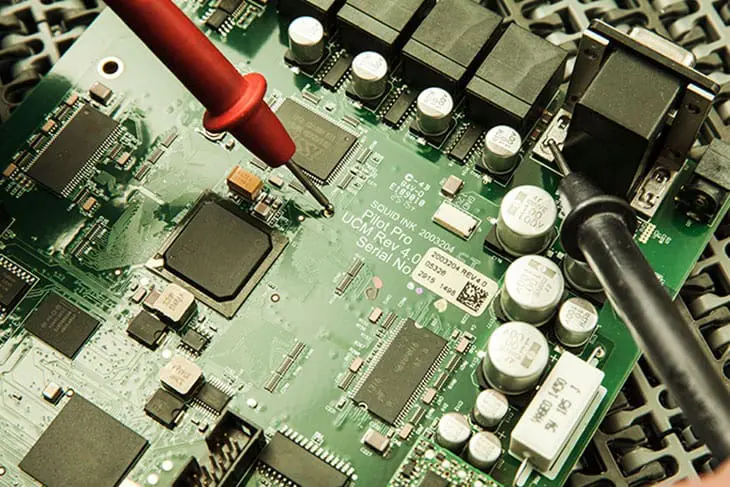

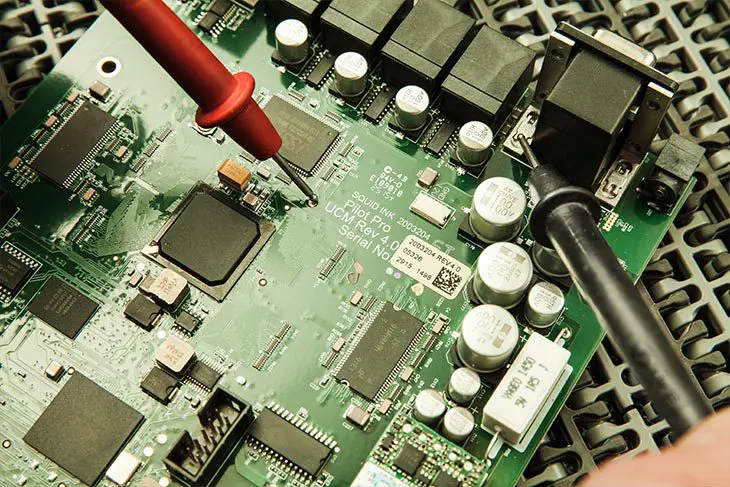

The Engage Packaging Group Support Assurance Program is designed to help users protect their investment and provide peace of mind on their packaging line. Our certified technicians will help extend the life of your machines while restoring the equipment’s original functionality and capability.

Two-Year Preventative Maintenance Program

Preventative maintenance is one of the best ways to ensure your existing equipment will continue to run at the production levels found in new packaging equipment. Engage Packaging Group’s comprehensive program includes:

Installation and Training

We provide installation and training services for all of our Eastey and AFM equipment. At the time of installation, our technician will train you on the theory of operation and general preventative maintenance of your machines.

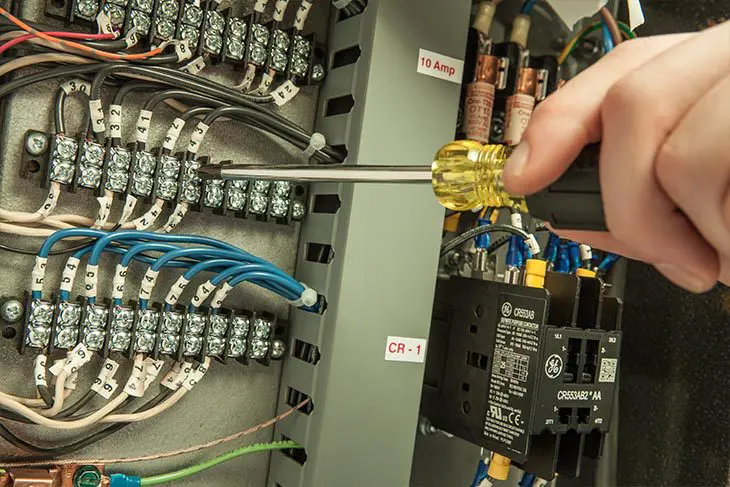

Equipment Audits, On-Site Service, and Upgrades

Optimize the reliability and efficiency of your packaging machinery with our on-site equipment audits. Our technician will assess, repair, replace, or adjust parts of your equipment to ensure your equipment is running at maximum efficiency. Engage Packaging Group also provides on-site repair and machine upgrade services.

Technical Support and Spare Parts Kits

Engage Packaging Technicians are available with installation and programming questions, mechanical problems, or service questions. Our service technicians can also provide Return Authorization numbers if you need to return components for warranty or non-warranty repair. In addition, Engage Packaging Technicians can recommend a Spare Parts Kit for your equipment to ensure you have common wear parts on hand.

Preventative maintenance is one of the best ways to ensure your equipment will continue to run at the production levels found in new packaging equipment. Our comprehensive program includes scheduled maintenance visits, technician-recommended machine enhancements, detailed equipment reports, machine training, and more.

Our technicians will assess, repair, replace, or adjust parts of your equipment to ensure your production is running at maximum efficiency. Engage Packaging Group also provides on-site repair and machine upgrade services. Technicians will evaluate and offer recommendations for refurbishing and upgrading machines based on the condition of your machine.

Do you want peace of mind knowing that your equipment is installed correctly and running properly from the initial startup? We provide installation and training services for all of our Eastey and AFM equipment. At the time of installation, our technician will train you on the theory of operation and general preventative maintenance of your machines.

We know that you can’t always predict when a part will wear out on your machine. That is why we maintain a large inventory of common wear items to keep you up and running. Our service technicians can also provide Return Authorization numbers if you need to return components for warranty or non-warranty repair. In addition, Engage Packaging Technicians can recommend a Spare Parts Kit for your equipment to ensure you have common wear parts in hand.