How Modern Shrink Packaging Can Reduce Material Waste

In today’s manufacturing and distribution environments, sustainability is no longer a nice-to-have—it’s a must. As companies look for ways to reduce their environmental footprint while maintaining packaging efficiency, modern shrink packaging has emerged as a practical and impactful solution.

Let’s take a closer look at how Eastey’s modern shrink-packaging technology is helping manufacturers and packagers cut down on material waste, lower costs, and move toward greener operations.

The Problem with Traditional Packaging

Traditional packaging methods, such as excessive void fill, and oversized shrink films, often lead to material overuse and waste. Not only does this increase packaging costs, but it also contributes to higher volumes of landfill waste and greater environmental impact.

With growing pressure from consumers and regulatory bodies to embrace sustainability, outdated packaging practices can hinder a company’s progress and brand reputation.

Enter Modern Shrink Packaging

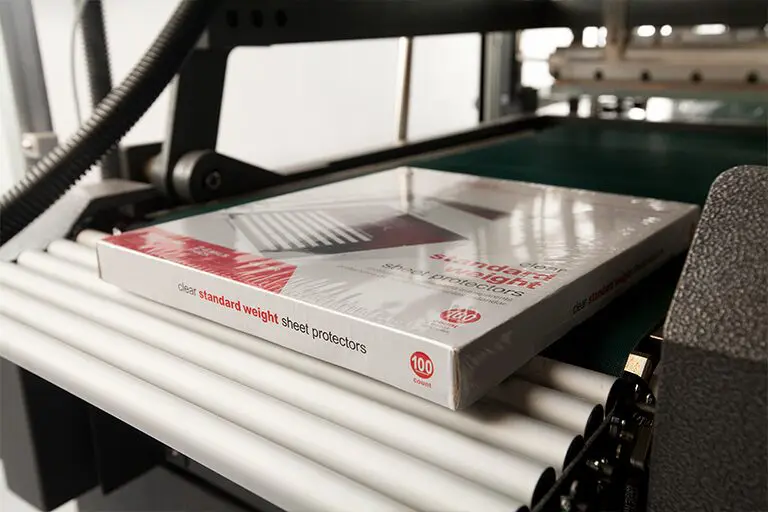

Shrink packaging uses heat to tightly wrap plastic film around a product or bundle. Advances in shrink packaging equipment and materials have made it possible to achieve tight, protective, and professional packaging with significantly less material than in the past.

Here’s how Eastey’s shrink-packaging systems reduce waste:

1. Precision Film Application

Eastey’s modern shrink wrappers and tunnels are designed with improved controls, automation, and precision. This allows operators to apply the exact amount of shrink film needed—no more, no less. Reducing excess film cuts down on waste and minimizes film scraps during operation.

2. Thinner, Stronger Films

Today’s shrink films are engineered to be thinner yet stronger than older versions. Manufacturers can now use lower-gauge film without compromising durability or product protection. This change alone can reduce material usage by up to 50% in some cases.

3. Automated Equipment Reduces Human Error

Manual packaging often leads to inconsistent film usage and more waste. Eastey’s automated shrink-packaging systems maintain consistent tension, heat levels, and seal strength, resulting in better film control and fewer errors—meaning less wasted material from rework or misapplication.

4. Multi-Pack Efficiency

Eastey’s shrink packaging excels at bundling multiple products together—like cans, bottles, or cartons—without the need for boxes or trays. This secondary packaging method replaces bulky corrugate, helping companies reduce the overall amount of packaging material per shipment.

The Environmental & Economic Benefits

Less material waste means less plastic entering the waste stream and fewer resources consumed in manufacturing packaging materials. But it’s not just about sustainability—there’s also a clear economic upside:

- Lower packaging costs

- Reduced shipping weights

- Fewer changeovers and less downtime

- Improved packaging consistency and aesthetics

Modern shrink packaging offers a win-win scenario: better for the environment and better for your bottom line.

Final Thoughts

If your business is still using outdated packaging systems, now is the time to consider an upgrade. Eastey’s shrink-packaging technology delivers cleaner, leaner, and more sustainable results—without sacrificing speed, safety, or reliability.

Looking to reduce material waste in your packaging line? Talk to the experts at Eastey. Our shrink-packaging solutions are designed with performance, durability, and sustainability in mind.