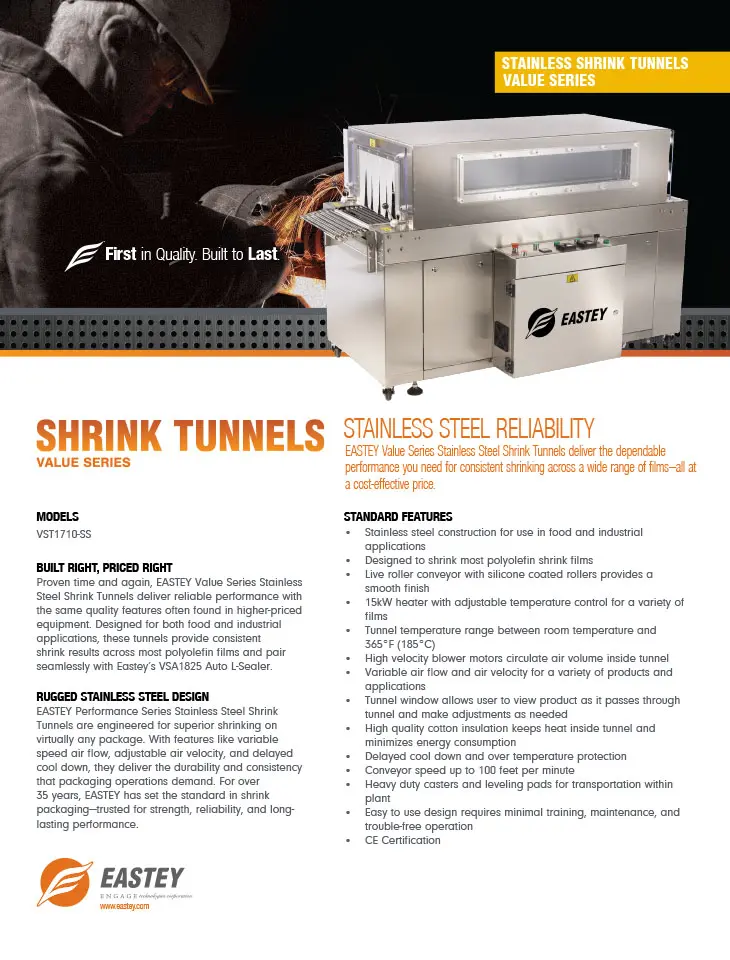

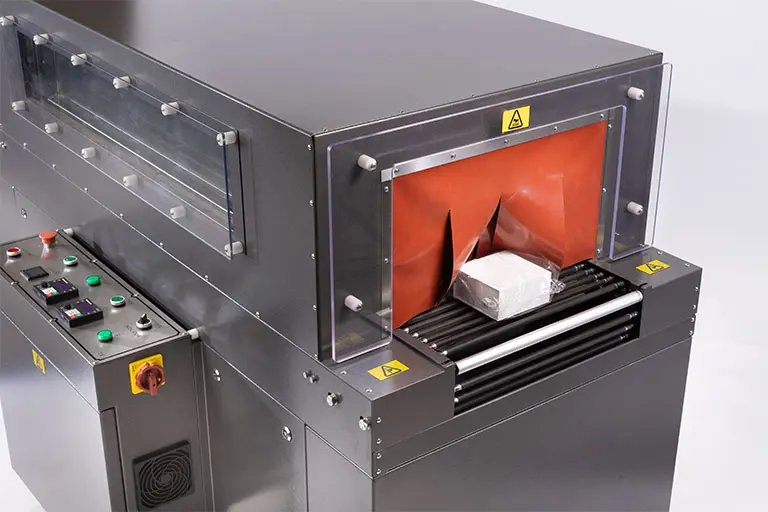

Shrink Tunnel

Stainless Steel Value Series VST1710

- Stainless steel construction for use in food and industrial applications

- Designed to shrink most polyolefin shrink films

- Live roller conveyor with silicone coated rollers provides a smooth finish

- 15kW heater with adjustable temperature control for a variety of films

- Tunnel temperature range between room temperature and 365°F (185°C)

BUILT RIGHT, PRICED RIGHT

Proven time and again, EASTEY Value Series Stainless Steel Shrink Tunnels deliver reliable performance with the same quality features often found in higher-priced equipment. Designed for both food and industrial applications, these tunnels provide consistent shrink results across most polyolefin films and pair seamlessly with Eastey’s VSA1825 Auto L-Sealer.

RUGGED STAINLESS STEEL DESIGN

EASTEY Performance Series Stainless Steel Shrink Tunnels are engineered for superior shrinking on virtually any package. With features like variable speed air flow, adjustable air velocity, and delayed cool down, they deliver the durability and consistency that packaging operations demand. For over 35 years, EASTEY has set the standard in shrink packaging—trusted for strength, reliability, and long-lasting performance.

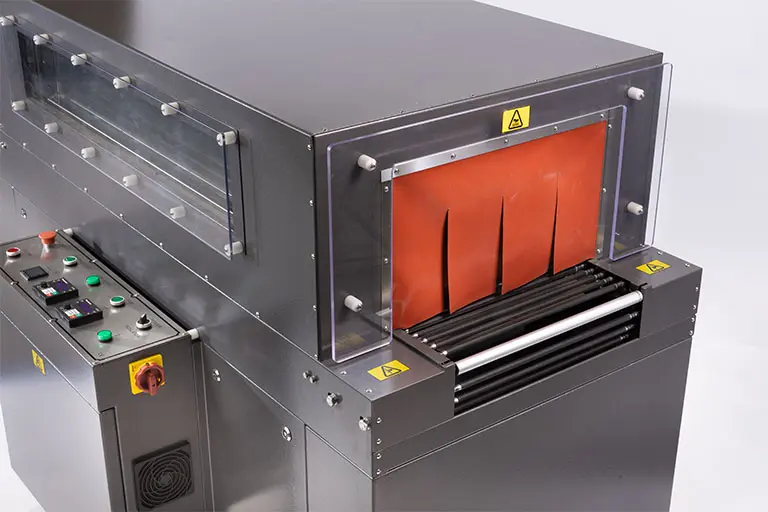

Live Roller Conveyor – Silicone roller conveyor provides a clean, finished look for retail packaging application.

Control Panel – Easy to use control panel allows users to adjust for their specific application.

Window – Tunnel window allows operator to view product as it passes through tunnel and make adjustments as needed.

Positive shrinking on polyolefin films.

Videos

Shrink Samples

- Stainless steel construction for use in food and industrial applications

- Designed to shrink most polyolefin shrink films

- Live roller conveyor with silicone coated rollers provides a smooth finish

- 15kW heater with adjustable temperature control for a variety of films

- Tunnel temperature range between room temperature and 365°F (185°C)

- High velocity blower motors circulate air volume inside tunnel

- Variable air flow and air velocity for a variety of products and applications

- Tunnel window allows user to view product as it passes through tunnel and make adjustments as needed

- High quality cotton insulation keeps heat inside tunnel and minimizes energy consumption

- Delayed cool down and over temperature protection

- Conveyor speed up to 100 feet per minute

- Heavy duty casters and leveling pads for transportation within plant

- Easy to use design requires minimal training, maintenance, and trouble-free operation

- CE Certification