What Are the Latest Trends in Packaging Machinery?

The packaging industry continues to evolve as manufacturers look for smarter, more flexible equipment that can adapt to changing market demands. From traceability requirements to shorter production runs, today’s packaging machinery must balance efficiency, scalability, and cost.

According to industry experts, several key trends are shaping purchasing decisions across many product markets:

- Smart packaging technology such as QR codes and track-and-trace

- Modular machinery that allows operations to grow over time

- Compact equipment designed for artisan and short-run production

- Increased automation to optimize productions lines

- Digital interfaces with memory functions and touchscreens

How Eastey Aligns with Today’s Packaging Machinery Trends

As packaging operations evolve, manufacturers are seeking equipment that delivers reliability, efficiency, and room to grow—without overextending capital budgets. Eastey’s packaging machinery lineup closely aligns with the trends shaping modern packaging environments.

Smart Packaging Technology Compatibility

Smart packaging has become a critical component of product traceability, brand engagement, and regulatory compliance. While Eastey machinery focuses on sealing, bundling, and shrink packaging, it integrates seamlessly into smart packaging workflows.

As a sister company, Squid Ink provides industrial coding and marking solutions that apply QR codes, barcodes, variable data, and track-and-trace information directly to products and packaging. When paired together, Eastey packaging equipment and Squid Ink CoPilot printing systems create a cohesive solution—allowing manufacturers to adopt smart packaging technologies without replacing existing machinery or overhauling their production lines.

Modular Machinery Designed for Growth

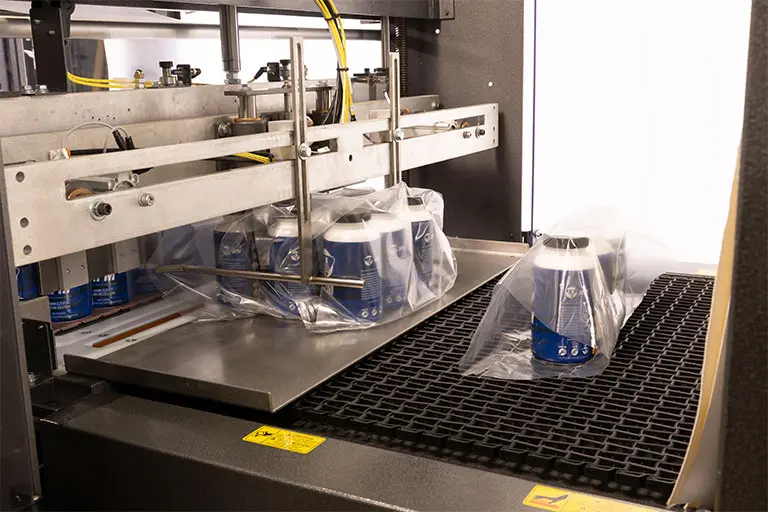

One of Eastey’s defining strengths is its modular approach to packaging equipment. Many Eastey machines can be configured with optional infeed and outfeed conveyors, shrink tunnels, or additional automation components as production requirements increase.

This modular design allows businesses to start with a semi-automatic system and scale over time, protecting their initial investment while supporting future growth—whether that means higher throughput, added automation, or expanded product lines.

Compact Equipment for Short-Run and Artisan Production

As demand grows for artisan, private-label, and short-run products, compact packaging machinery has become increasingly important. Eastey offers a wide range of footprint-friendly equipment ideal for smaller production environments.

From entry-level L-bar sealers to space-saving shrink tunnels and bundlers, Eastey machines deliver industrial-grade performance without requiring large floor space—making them well suited for startups, co-packers, and specialty producers.

Automation for Small-Batch Filling and Sealing

Automation is no longer reserved for high-volume manufacturers. Eastey’s automatic sealers, bundlers, case erectors and case tapers provide consistent, repeatable results while still giving operators hands-on control.

This balance of automation and flexibility is especially valuable in many product applications, where frequent changeovers, multiple SKUs, and small batch sizes are common. Eastey equipment helps improve efficiency and consistency without sacrificing adaptability.

Digital Interfaces and Operator-Friendly Controls

Ease of use is another growing priority in packaging machinery. Many Eastey machines feature digital controls that simplify setup, operation, and repeatability.

Adjustable settings, precise temperature controls, and repeatable parameters help reduce setup time, minimize operator error, and maintain consistent packaging quality—even across multiple shifts or product variations.

The Shift Toward Automatic Packaging Solutions

Across the packaging industry, manufacturers are increasingly choosing automatic equipment that strikes the right balance between cost, flexibility, and performance. Eastey fits squarely within this trend by offering rugged, easy-to-use packaging machinery designed to adapt as production demands evolve.

For businesses in food, supplements, and many more, Eastey—alongside Squid Ink’s coding and marking solutions—provides a practical, scalable path forward: packaging systems built to grow with your operation and support today’s most important industry trends.