How Automated Case Sealing Reduces Labor Costs and Boosts Productivity

Why Manufacturers Trust Eastey for Smarter Packaging Solutions

In today’s fast-paced manufacturing environment, efficiency isn’t just a goal — it’s a necessity. As businesses face increasing labor costs, supply chain pressures, and growing demand, packaging operations are under more pressure than ever to perform.

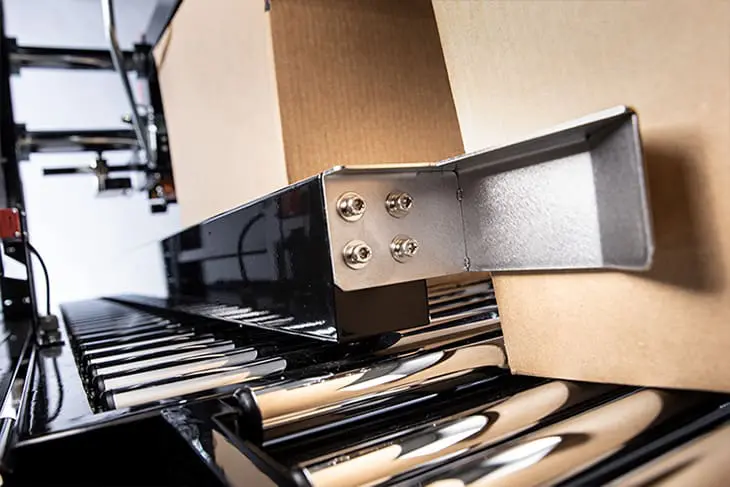

One of the most effective ways to boost efficiency while reducing labor costs is through automated case sealing. Eastey’s rugged, reliable line of case sealers offers manufacturers a simple way to eliminate bottlenecks, reduce manual labor, and improve throughput — all while ensuring a professional, consistent seal every time.

The Problem with Manual Case Sealing

For operations relying on manual labor to fold flaps and apply tape to boxes, the drawbacks are significant:

- ❌ High Labor Costs: Manually sealing boxes requires multiple employees, especially at scale.

- ❌ Inconsistent Results: Human error leads to crooked tape, open flaps, or improperly sealed cases.

- ❌ Slow Throughput: Manual sealing slows down production lines, creating costly bottlenecks.

- ❌ Increased Fatigue & Turnover: Repetitive manual tasks can lead to worker fatigue, injury, and higher turnover rates.

In a competitive industry, these issues directly impact your bottom line.

How Eastey’s Automated Case Sealers Solve This

Eastey offers a full line of automatic and semi-automatic case sealers designed to streamline box sealing. Here’s how automation makes an immediate impact:

1. Reduced Labor Costs

- One Eastey case sealer can replace manual labor on the packaging line, reallocating staff to higher-value tasks.

- On our fully automated case sealers, operators simply load the box — the machine handles flap folding and tape application.

2. Increased Productivity

- Automated case sealers run continuously, matching, or exceeding the pace of upstream production.

- Machines can process hundreds of boxes per hour with consistent precision.

- No breaks, fatigue, or slowdowns — keeping your production line moving at peak efficiency.

3. Consistent, Professional Results

- Uniform tape application improves the appearance and integrity of every case.

- Eliminates costly rework or failed seals that can lead to damaged shipments or customer complaints.

4. Reduced Product Damage and Returns

- Properly sealed cases are more secure in transit, protecting your products and reducing damage-related costs.

5. Minimal Maintenance, Maximum Uptime

- Eastey machines are built for 24/7 operation with durable steel construction and simple maintenance requirements.

- Designed for long life, keeping your operation running with fewer interruptions.

Real-World Impact: The ROI of Automation

Many Eastey customers report that their investment in automated case sealing pays for itself within months. Consider this:

- Reduced labor costs.

- Savings from fewer damaged products, faster throughput, and lower maintenance, and the ROI grows even faster.

Why Choose Eastey?

✔ Made in the USA: Heavy-duty construction you can rely on.

✔ Simple Integration: Compatible with most production lines.

✔ Easy Operation: Intuitive controls with minimal training required.

✔ Low Maintenance: Built to last with minimal service requirements.

✔ Industry Versatility: Used in food & beverage, electronics, pharmaceuticals, and more.

Conclusion: Automate for a Stronger Bottom Line

Automating case sealing with Eastey is one of the simplest, most cost-effective ways to reduce labor costs while improving packaging consistency, throughput, and product protection. Whether you’re sealing 50 or 500 boxes an hour, our machines are built to handle the load — and deliver measurable ROI.

Ready to boost productivity and cut costs? Contact the Eastey team today to learn more, schedule a demo, or get a custom quote tailored to your operation.