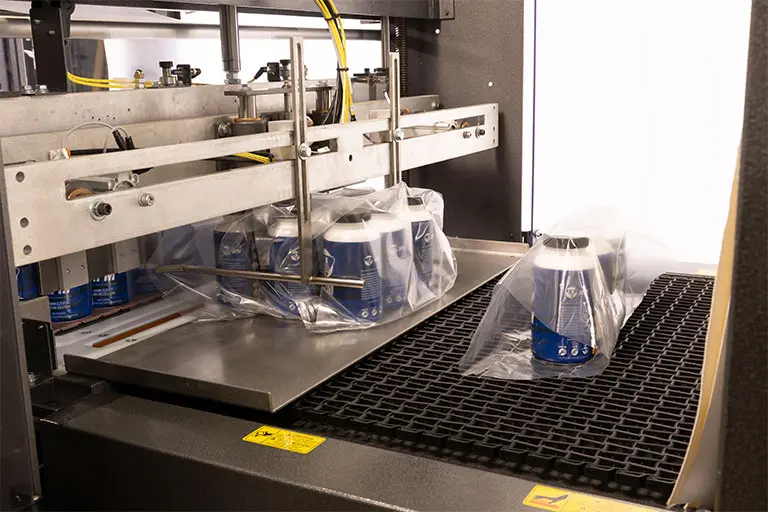

Automatic Combo Bundler

ECB25A

- Designed for positive sealing of polyethylene shrink films

- 25” hot knife seal system ensures consistent “bull’s-eye” closures

- Fixed lower seal bar and magnetic hold for clean, reliable seals

- Accommodates film up to 25” wide and 12” OD

PROVEN QUALITY. PROVEN VALUE.

Trusted by packagers nationwide, the ECB25A offers the same high-quality features found in machines costing much more. Engineered for collating, unitizing, and shrink wrapping, it ensures consistent results and maximum value.

HEAVY DUTY DESIGN. HEAVY DUTY RESULT.

Built tough on a ¼” cold rolled steel frame, Eastey’s Automatic Combo Bundler is designed to handle the day-to-day abuse of the most demanding bundling applications. A servo-controlled pusher and seal bar provide precise product handling and sealing accuracy, while the integrated sealer and tunnel share a single compact frame for fast setup and easy relocation on the plant floor. For over 35 years, Eastey has set the standard in shrink packaging solutions—and the ECB25A continues that legacy of performance and reliability.

Products enter the machine from the side

Servo controlled pusher moves a row of products off the conveyor and into the film area

Powered film unwind ensures smooth feed of film up to 12” max OD

Once the desired bundle size is configured (one row, two rows, etc.)

a seal is made

Full color HMI with industrial swing arm for easy operator access and visibility is available with optional remote access for monitoring or troubleshooting system

The sleeve wrapped bundle is conveyed into a high temperature convection heat tunnel

Blown warm air shrinks film around product bundle for a secure finish

The finished product is a tightly wrapped bundle

Videos

Shrink Samples

- Accommodates product up to 7.5” diameter x 11” tall

- Minimum product size: 1.5” diameter x 3” tall

- Left- or right-angle infeed for flexible integration

- Smooth product transfer with self-tracking conveyor and indexing system

- Soft-start infeed and outfeed conveyors minimize product shifting

- Servo-controlled pusher and seal bar for precision

- Speeds between 1 to 25 cycles per minute, depending on product size