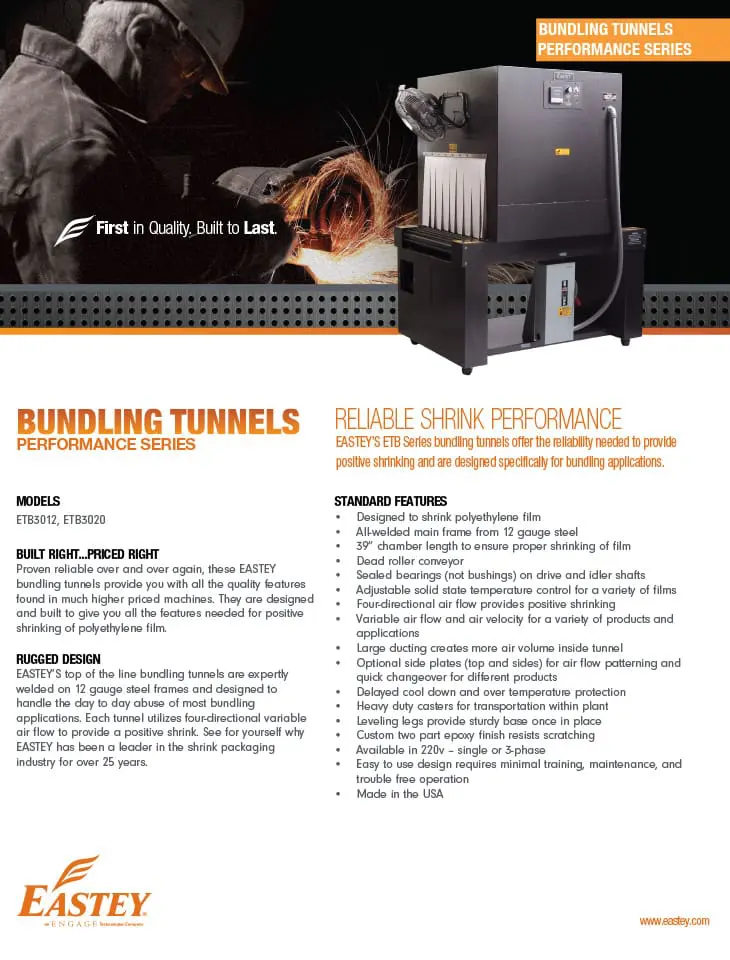

Bundling Tunnels

Performance Series

- Designed to shrink polyethylene film

- All-welded main frame from 12 gauge steel

- 39” chamber length to ensure proper shrinking of film

- Adjustable solid state temperature control for a variety of films

- Four-directional air flow provides positive shrinking

BUILT RIGHT...PRICED RIGHT

Proven reliable over and over again, these Eastey bundling tunnels provide you with all the quality features found in much higher priced machines. They are designed and built to give you all the features needed for positive shrinking of polyethylene film.

RUGGED DESIGN

Eastey's top of the line bundling tunnels are expertly welded on 12 gauge steel frames and designed to handle the day to day abuse of most bundling applications. Each tunnel utilizes four-directional variable air flow to provide a positive shrink. See for yourself why Eastey has been a leader in the shrink packaging industry for over 35 years.

Proven Eastey tunnels provide positive shrinking of polyethylene film.

Dead roller designed specifically for polyethylene films.

Easy to use control panel lets users adjust for their specific application.

Four directional air flow provides positive shrinking.

Videos

Shrink Samples

- Designed to shrink polyethylene film

- All-welded main frame from 12 gauge steel

- 39” chamber length to ensure proper shrinking of film

- Dead roller conveyor

- Sealed bearings (not bushings) on drive and idler shafts

- Adjustable solid state temperature control for a variety of films

- Four-directional air flow provides positive shrinking

- Variable air flow and air velocity for a variety of products and applications

- Large ducting creates more air volume inside tunnel

- Optional side plates (top and sides) for air flow patterning and quick changeover for different products

- Delayed cool down and over temperature protection

- Heavy duty casters for transportation within plant

- Leveling legs provide sturdy base once in place

- Custom two part epoxy finish resists scratching

- Available in 220v – single or 3-phase

- Easy to use design requires minimal training, maintenance, and trouble free operation

- Made in the USA