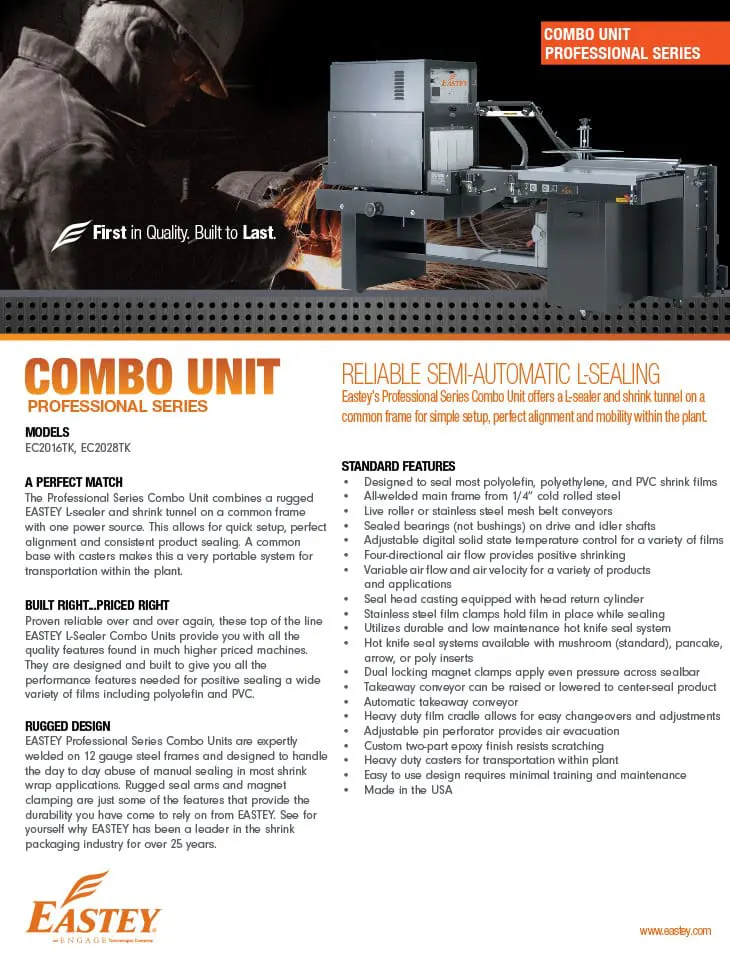

Combo Units

Professional Series

- Heavy-duty single frame welded construction

- Hot knife seal system

- Rugged stainless steel mesh belt, live or dead roller, and high temperature plastic tunnel conveyor options

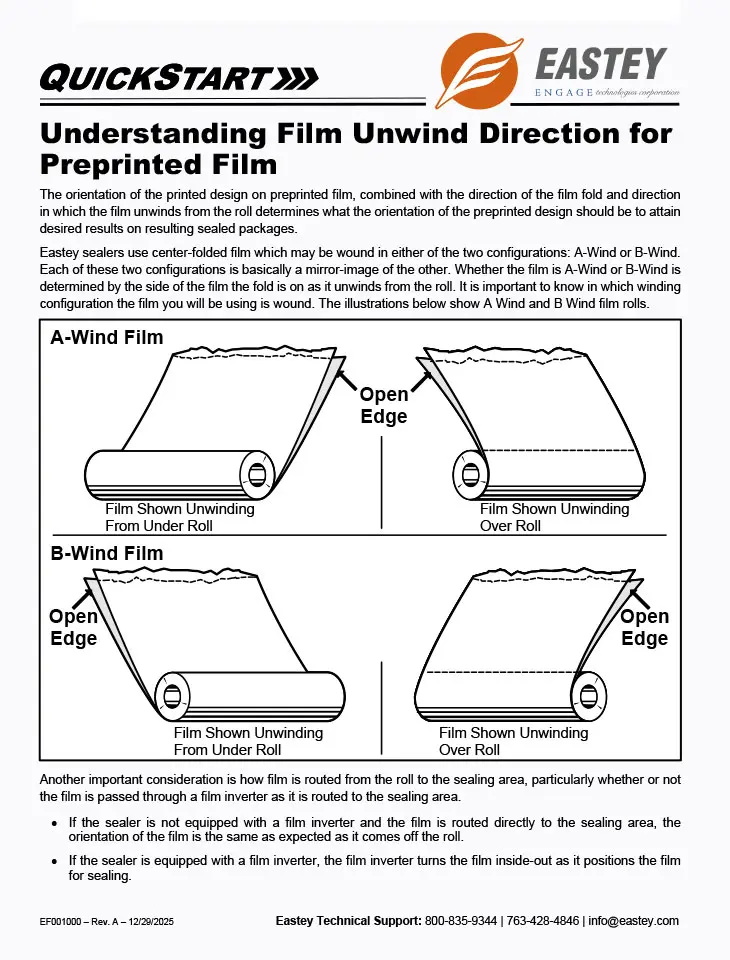

- Available powered film unwind and inverting head

- Single 220 or 480 VAC,1-phase power connection

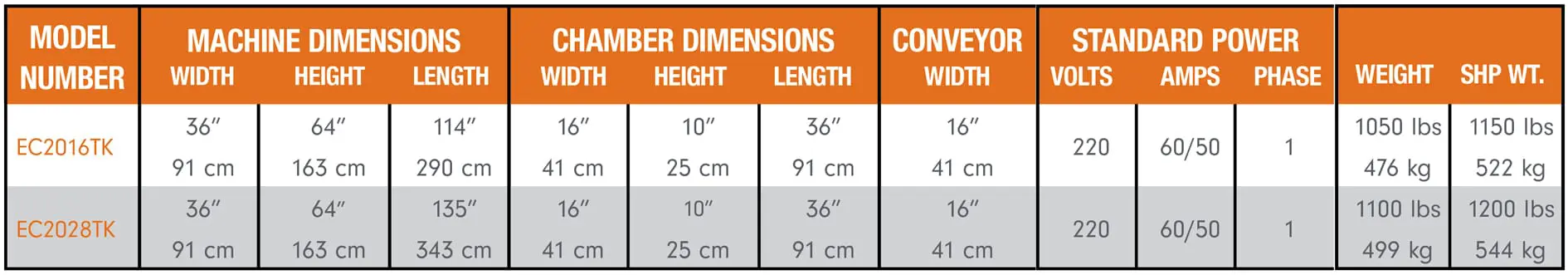

- 16” wide x 10” tall x 36” long tunnel chamber

- Seal size of 20”x16” or 20”x28”

- Maximum film size = 23”

BUILT RIGHT...PRICED RIGHT

Proven reliable over and over again, these top of the line EASTEY L-Sealer Combo Units provide you with all the quality features found in much higher priced machines. They are designed and built to give you all the performance features needed for positive sealing a wide variety of films including polyolefin and PVC.

RUGGED DESIGN

Eastey Professional Series Combo Units are expertly welded on 12 gauge steel frames and designed to handle the day to day abuse of manual sealing in most shrink wrap applications. Rugged seal arms and magnet clamping are just some of the features that provide the durability you have come to rely on from Eastey. See for yourself why Eastey has been a leader in the shrink packaging industry for over 35 years.

Seal head can be raised or lowered to center the seal on your product.

Adjustable pin perforator provides air evacuation in film which allows for proper film shrinkage.

Easy to use control panel lets users adjust temperature settings for their specific application.

Consistent air flow provides positive shrinking of polyolefin or PVC shrink films.

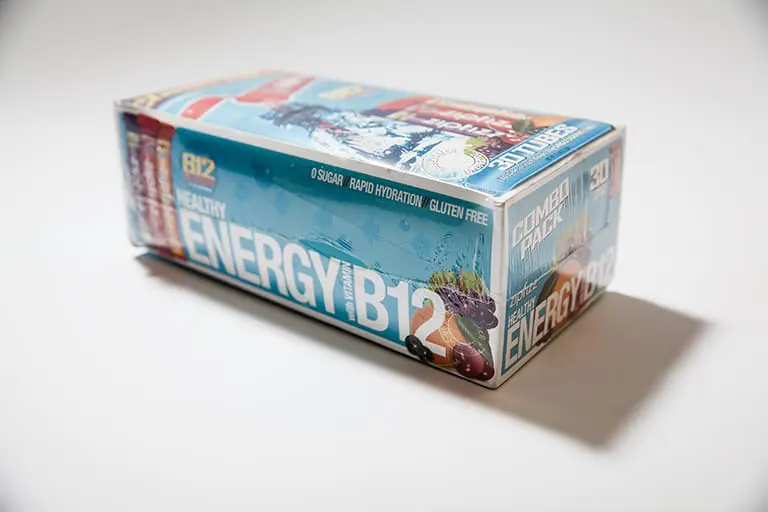

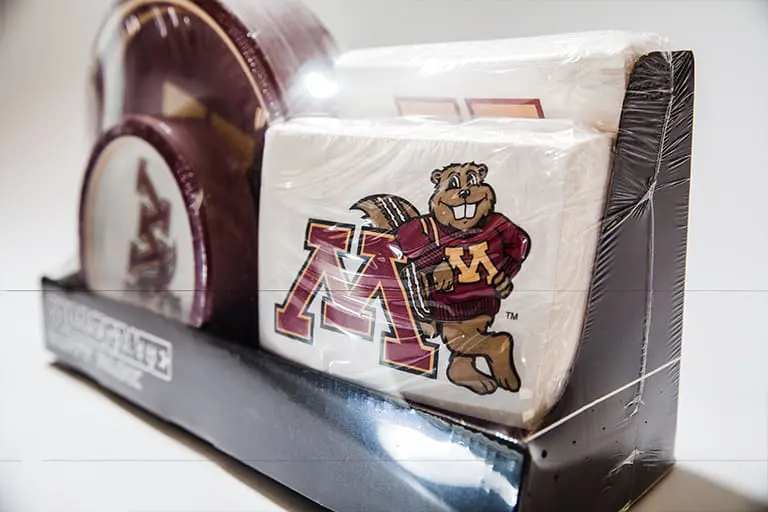

Videos

Shrink Samples

- Designed to seal most polyolefin, polyethylene, and PVC shrink films

- All-welded main frame from 1/4” cold rolled steel

- Live roller or stainless steel mesh belt conveyors

- Sealed bearings (not bushings) on drive and idler shafts

- Adjustable digital solid state temperature control for a variety of films

- Four-directional air flow provides positive shrinking

- Variable air flow and air velocity for a variety of products and applications

- Seal head casting equipped with head return cylinder

- Stainless steel film clamps hold film in place while sealing

- Utilizes durable and low maintenance hot knife seal system

- Hot knife seal systems available with mushroom (standard), pancake, arrow, or poly inserts

- Dual locking magnet clamps apply even pressure across sealbar

- Takeaway conveyor can be raised or lowered to center-seal product

- Automatic takeaway conveyor

- Heavy duty film cradle allows for easy changeovers and adjustments

- Adjustable pin perforator provides air evacuation

- Custom two-part epoxy finish resists scratching

- Heavy duty casters for transportation within plant

- Easy to use design requires minimal training and maintenance

- Made in the USA