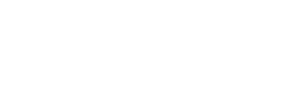

Automatic L-Sealers

Value Series VSA1825 Stainless Steel

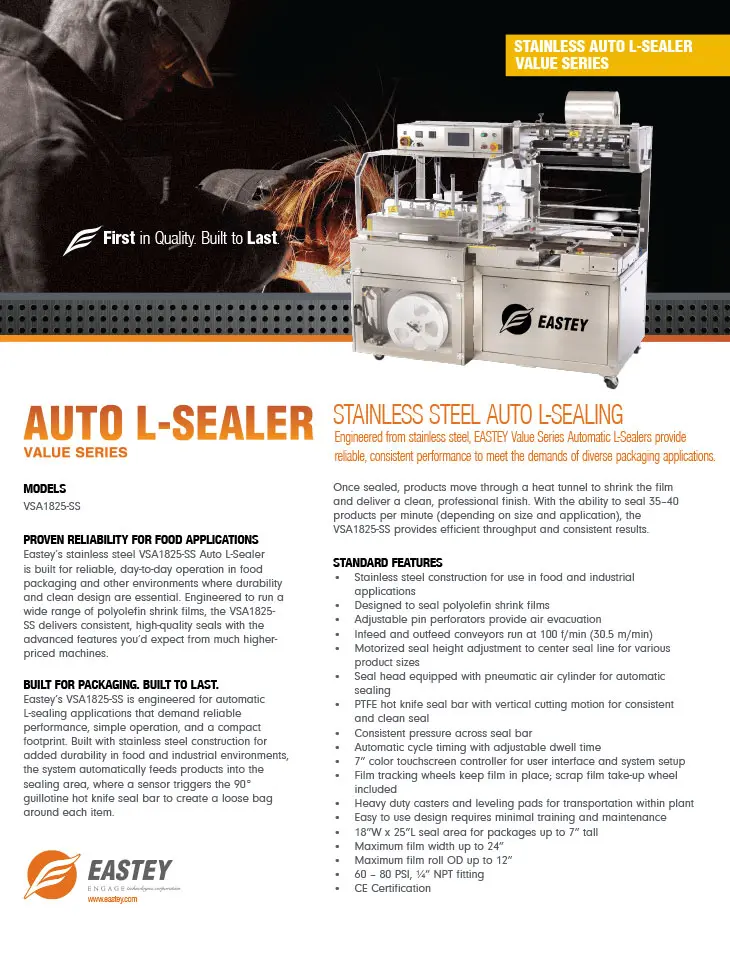

- Stainless steel construction for use in food and industrial applications

- Designed to seal polyolefin shrink films

- Adjustable pin perforators provide air evacuation

- Infeed and outfeed conveyors run at 100 f/min (30.5 m/min)

- Motorized seal height adjustment to center seal line for various product sizes

- Seal head equipped with pneumatic air cylinder for automatic sealing

- PTFE hot knife seal bar with vertical cutting motion for consistent and clean seal

- Consistent pressure across seal bar

PROVEN RELIABILITY FOR FOOD APPLICATIONS

Eastey’s stainless steel VSA1825-SS Auto L-Sealer is built for reliable, day-to-day operation in food packaging and other environments where durability and clean design are essential. Engineered to run a wide range of polyolefin shrink films, the VSA1825-SS delivers consistent, high-quality seals with the advanced features you’d expect from much higher-priced machines.

BUILT FOR PACKAGING. BUILT TO LAST.

Eastey’s VSA1825-SS is engineered for automatic L-sealing applications that demand reliable performance, simple operation, and a compact footprint. Built with stainless steel construction for added durability in food and industrial environments, the system automatically feeds products into the sealing area, where a sensor triggers the 90° guillotine hot knife seal bar to create a loose bag around each item.

Hot Knife Seal Bar - Vertical cutting motion with PTFE hot knife delivers a consistent seal every time

Multiple Pin Perforators - Adjustable pin perforators provide air evacuation during shrink process

Film Inverter - Opens film to create a loose bag around the product

7” Color Touchscreen – User interface features simple menus for easy operation and adjustments required for a variety of applications.

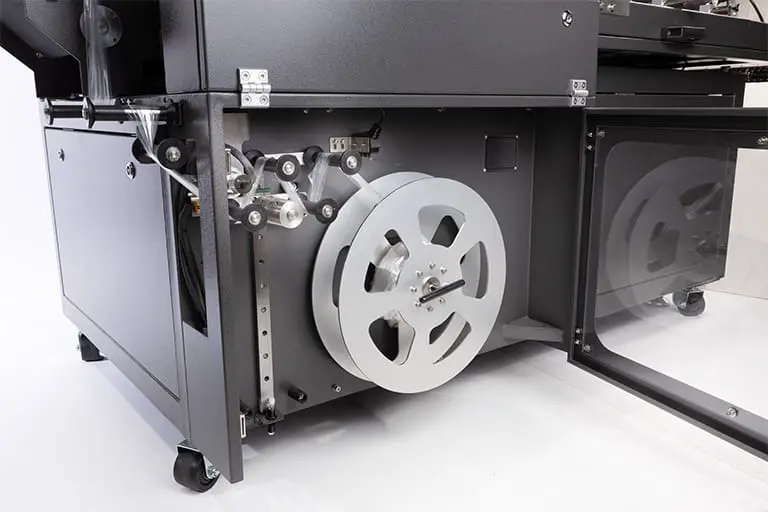

Scrap Wind Roller – Take-up wheel for safe and convenient removal of scrap film.

Exit Conveyor – Provides a smooth transition from the sealer to the shrink tunnel.

Videos

Shrink Samples

- Stainless steel construction for use in food and industrial applications

- Designed to seal polyolefin shrink films

- Adjustable pin perforators provide air evacuation

- Infeed and outfeed conveyors run at 100 f/min (30.5 m/min)

- Motorized seal height adjustment to center seal line for various product sizes

- Seal head equipped with pneumatic air cylinder for automatic sealing

- PTFE hot knife seal bar with vertical cutting motion for consistent and clean seal

- Consistent pressure across seal bar

- Automatic cycle timing with adjustable dwell time

- 7” color touchscreen controller for user interface and system setup

- Film tracking wheels keep film in place; scrap film take-up wheel included

- Heavy duty casters and leveling pads for transportation within plant

- Easy to use design requires minimal training and maintenance

- 18”W x 25”L seal area for packages up to 7” tall

- Maximum film width up to 24”

- Maximum film roll OD up to 12”

- 60 – 80 PSI, ¼” NPT fitting

- CE Certification